Wind Turbine Behavior and Control (Part 2) – Nanjing Oulu Electric

Nanjing Oulu Electric Co., Ltd.

Company Profile

A high-tech enterprise specializing in R&D, production, and system integration of:

New energy power generation (wind/PV hybrid systems)

Industrial automation (drives, servo control, EV motor controllers)

Core Products:

Wind Turbines (300W–10MW)

Hybrid Controllers/Inverters

Telecom Monitoring Systems

Motor Drives (PMSM/Servo/VFD)

Wind Turbine Behavior Analysis (Part 2)

1. Operational Divergence: Large vs. Small Wind Turbines

| Parameter | Large Turbines (80m Hub) | Small Turbines (8m Hub) |

|---|---|---|

| Wind Profile | V<sub>80m</sub>=10m/s (Class I) | V<sub>8m</sub>=6.3m/s (Class III) |

| Turbulence | 12% (IEC 61400-1 NWP) | >30% (Boundary layer effect) |

| Design Basis | V<sub>design</sub>=50m/s (Typhoon) | V<sub>design</sub>=1.4V<sub>ave</sub>=11m/s (BWEA) |

Key Findings:

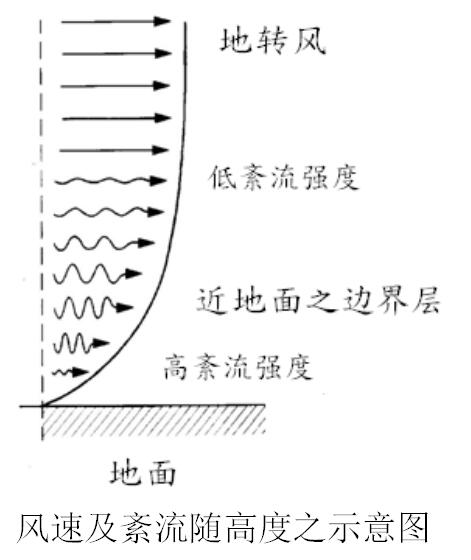

Height-Velocity Relationship:

Follows V=V<sub>hub</sub>(Z/Z<sub>hub</sub>)<sup>0.2</sup> (IEC 61400-1 NWP)

At 10m/s (80m): 8m height velocity drops to 6.3m/s (-37%)

Class Rationale:

Small turbines rarely encounter Class I winds (16m/s at 80m ≈ typhoon)

V<sub>design</sub>=11m/s (AWEA/BWEA) balances cost & safety

2. Control System Innovations

Breakthrough Technologies:

Active Pitch/Yaw Control:

Real-time blade adjustment (storm survival)

MEMS-based vibration damping

Tower Resonance Avoidance:

Software-limited RPM below 1P/3P frequencies

Field Data: Our 5MW turbine maintains <5% power fluctuation in Class III turbulence.

Why Nanjing Oulu?

Patent-protected active control algorithms

IEC/GL-certified simulation models

Custom solutions for low-wind/high-turbulence sites

Behavioral Differences Between Large and Small Wind Turbines

1. Large Wind Turbines (Class I/II, 80m+ Hub Height)

Characteristics:

High inertia: Slow acceleration/deceleration ("like a heavy truck")

Stable wind profile: Low turbulence (10–15%) at high altitudes

Efficiency:

Maintains optimal tip-speed ratio (λ) for max C<sub>p</sub>≈0.5 (e.g., Enercon E112)

Active pitch/yaw control ensures λ stays within ±5% of target

Control Advantage:

Real-time wind speed data (anemometers/LIDAR) enables precise λ calculation.

2. Small Wind Turbines (Class III/IV, <20m Hub Height)

Characteristics:

Low inertia: Rapid acceleration/deceleration ("like a sports car")

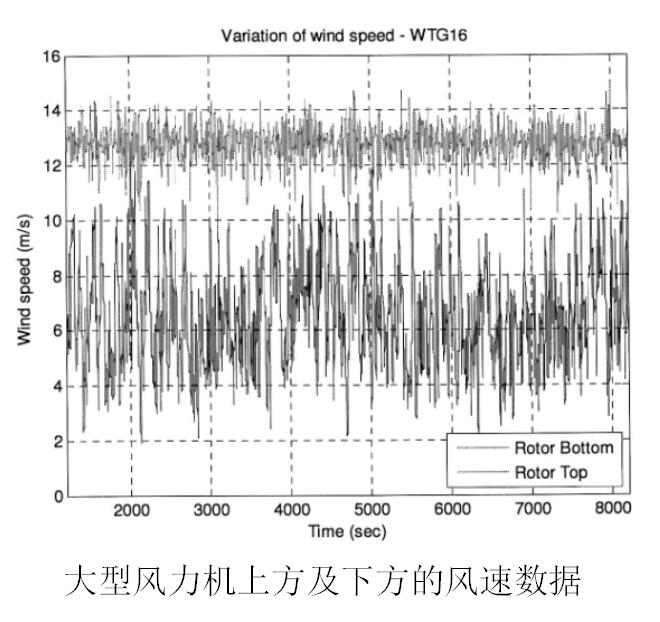

High turbulence: 30%+ due to ground boundary layer effects

Efficiency Challenges:

C<sub>p</sub> rarely exceeds 0.35 (vs. blade design potential of 0.45+)

No anemometer: Lacks wind speed data → impossible to calculate λ in real time

Key Limitations:

Dynamic RPM Swings:

Fast wind gusts cause ±20% RPM fluctuations, pushing λ off optimal.

Passive Control Dominance:

Tail-vane yaw and stall regulation cannot compensate for rapid λ shifts.

Technical Comparison

| Parameter | Large Turbines | Small Turbines |

|---|---|---|

| Inertia | High (slow response) | Low (fast response) |

| Wind Data | Anemometer/LIDAR available | Typically none |

| C<sub>p</sub> | 0.45–0.50 (controlled) | 0.25–0.35 (uncontrolled) |

| λ Stability | ±5% (active pitch control) | ±30% (passive systems) |

Nanjing Oulu’s Solutions for Small Turbines

Adaptive Load Dumping:

Dynamic resistor banks stabilize RPM during gusts.

Indirect λ Estimation:

Algorithm predicts wind speed from generator current harmonics.

Mechanical Upgrades:

Flywheel add-ons to increase effective inertia.

Case Study: Our FD-5kW model achieved C<sub>p</sub>=0.38 in Class IV winds via hybrid passive/active braking.