Wind Turbine Behavior and Control (Part 1)

Nanjing Oulu Electric Co., Ltd. is an enterprise dedicated to sustainable development and continuous technological innovation. Starting from early low-tech micro wind turbines to more advanced small wind turbines, the company has responded to the government's policy of transforming China from a manufacturing giant to a manufacturing powerhouse in recent years. Through in-depth research on wind turbine operational behavior and control system theory, and by overcoming numerous technical challenges, the company has established its own wind turbine system behavior and control theory. It has successfully developed both hardware and software for wind turbine control systems, which have been effectively applied to actively controlled wind turbines featuring pitch adjustment, yaw control, and braking mechanisms. This control system is also adaptable to more advanced medium and large-scale wind turbines, breaking through foreign technological barriers.

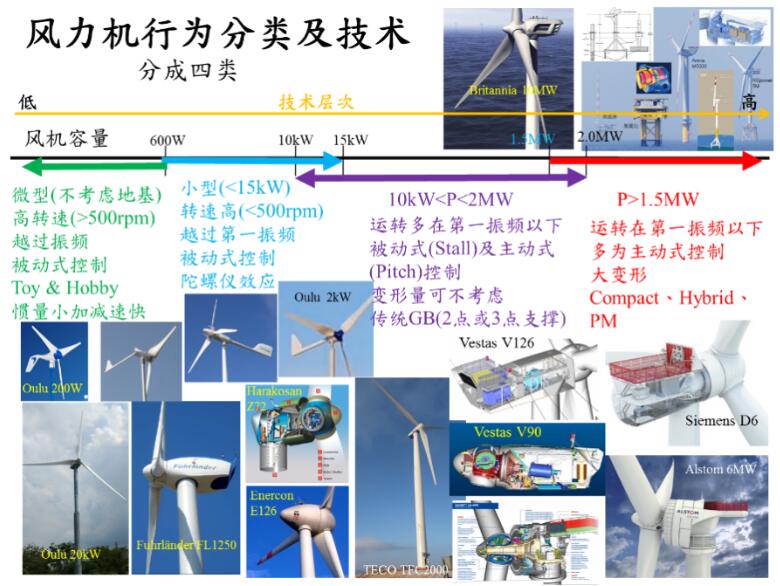

Below is an explanation of wind turbine behavior, which can be categorized into four types based on characteristics (see diagram above):

a. Power below 1kW: Micro Wind Turbine

These turbines are small and lightweight, often using guyed towers without concrete foundations to reduce costs. Their characteristics include high-speed operation (typically >500 rpm, sometimes exceeding 1000 rpm), frequently passing through one or two resonant frequencies. Most employ passive control systems, such as tail-vane yaw systems with slip rings. Due to low inertia, acceleration/deceleration is rapid, making constant speed difficult. Primarily used for toys and hobbies.

Protection mechanism: Typically activates a three-phase short-circuit brake upon exceeding safe RPM. A few models include unloading resistors to reduce speed before braking, preventing generator burnout.

Commonly used in wind-solar hybrid systems.

b. Power range ~1kW to 15kW: Small Wind Turbine with passive control

Characteristics include operational speeds below 500 rpm with rapid speed variations, requiring traversal of the first resonant frequency. Special attention must be paid to gyroscopic effects at high speeds to prevent turbine locking (hindering yaw adjustment) and subsequent failure of the auto-furl mechanism. The yaw system typically employs a passive tail-vane design incorporating slip rings.

Protection mechanisms: Commonly utilize load dumping, tail-furling, passive yaw, passive pitch adjustment, and three-phase generator short-circuit braking.

Frequently applied in standalone or grid-tied wind-solar-diesel hybrid smart management systems.

c. Power range ~10kW to 2MW: Small/Medium/Large Wind Turbine with active control

Key characteristics:

Operates primarily below the first resonant frequency

Pitch control: Passive (stall-regulated) or active (pitch-regulated) systems

Active yaw control

Negligible system deformation (typically disregarded)

Drive train options: Direct-drive or geared (with 2/3-point bearing support)

Doubly-fed induction generators (DFIG) dominate this segment

Design rationale:

While passive control suffices for sub-15kW turbines (a/b types), this category mandates active control to address:

Structural demands: Larger rotors induce significant gyroscopic moments and bending stresses

Grid compliance: Strict requirements for frequency stability and power quality

Load management: Essential for mitigating mechanical fatigue in multi-MW systems

Protection systems:

Primary: Pitch-regulated aerodynamic braking

Secondary: Mechanical disc brakes (emergency use)

Tertiary: Dynamic resistor banks for grid fault ride-through

d.功率大于1.5MW:大型及超大型风力机(LargeWindTurbine)。

运转在第一振频以下;采用主动式变桨及转向控制;需考虑大变形;为减轻重量会采直驱或传动链简化措施如Compact、Hybrid;离岸风电用之风力机多已采5MW以上机种;发电机为减少滑环之维护有采永磁发电机(PMSG)之趋势。