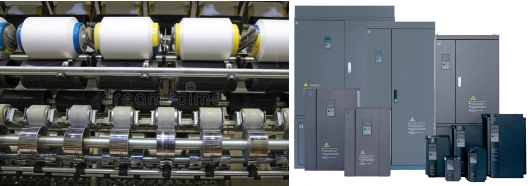

The use of Nanjing Euroverter frequency converters in the textile industry

The textile industry is a traditional and long-established sector where most equipment tends to be outdated. It is characterized by labor-intensive operations, harsh working environments, and high energy consumption. Therefore, achieving automation and maximizing energy efficiency is critically important.

In recent years, frequency converters have been playing an increasingly vital role in the textile industry, contributing significantly to energy savings, equipment performance enhancement, and textile process optimization. Nanjing Euroverter frequency converters have now been widely adopted in the textile sector, helping customers improve production efficiency even under demanding operating conditions.

The application of frequency converters in the textile industry can significantly reduce power consumption. Before the adoption of frequency converters, to ensure sufficient starting torque and minimize grid impact, the installed power for air supply and high-inertia loads was typically 40%–50% higher than required, and transformer capacity was also substantially oversized. This not only resulted in wasted capital investment but also led to substantial no-load losses (copper and iron losses) in motors and transformers, incurring staggering electricity costs.

Thanks to the superior soft-start and constant torque capabilities of frequency converters, asynchronous motors can now achieve 100%–150% starting torque while limiting inrush current to near-rated levels. This eliminates the previous constraints imposed by motor capacity and grid impact. With frequency conversion, the issues of oversized motor capacity and excessive power waste are completely resolved.

Air conditioning is an essential facility in cotton mills, crucial for production. If fan efficiency remains constant, reducing airflow demand proportionally lowers fan speed, resulting in a cubic reduction in power consumption. Fans are widely used in textile equipment, predominantly driven by high-power AC motors, making them major energy consumers. Traditionally, fans operated at constant speed with airflow adjusted via dampers—a simple but inefficient method that increased pipeline losses and wasted energy. By adopting fan-specific frequency conversion for automatic speed regulation, energy waste can be fundamentally eliminated.

Features of Nanjing Euroverter Frequency Converters in the Textile Industry

Reduced Power Consumption & Lower Costs

Textile mills rely heavily on air conditioning systems. By implementing frequency converters, power consumption is reduced, leading to significant cost savings. Data from one company shows that 12 air conditioning units saved over 240,000 RMB annually, with average power consumption dropping by 6–7 percentage points.Simplified Mechanisms & Enhanced Performance

Using PLC (Programmable Logic Controller) or industrial computers in conjunction with frequency converters enables synchronized multi-motor operation. This allows precise control of mechanical movements based on production curves, simplifying mechanisms. For example:Roving frames eliminate cone drum transmissions by using AC variable frequency drives, resolving belt slippage and speed inaccuracy issues.

Spinning frames remove forming cams, eliminating pauses at the cam base and impact at the peak, ensuring well-shaped yarn bobbins for smooth unwinding in subsequent processes. Additionally, spindle speed adjustments via frequency converters reduce yarn breakage rates during bobbin size transitions.

Frequency Converter Technologies in Textile Applications

Textile machinery powered by frequency converters primarily use two types of AC motors:

Standard Y-series asynchronous motors – Suitable for machines with low speed precision and narrow speed ranges.

Dedicated variable-frequency asynchronous motors – Used in high-precision, wide-range applications.

Nanjing Euroverter’s experts outline different frequency converter types:

V/F Control (Open-Loop)

Simple and reliable.

Speed range: 10:1, precision 2%–5%.

Poor low-speed performance; used in knitting machines and less demanding textile equipment.

Sensorless Vector Control

Excellent low-speed torque.

Speed range: 20:1, precision 0.1%.

Superior acceleration, torque, and current-limiting features.

Ideal for dyeing and printing machinery.

Closed-Loop Vector Control (AC Servo Motors)

Speed range: 100:1.

Uses IGBT (Insulated Gate Bipolar Transistors) for high switching frequency, enabling fast response, high precision, and smart control.

Suitable for tension-sensitive applications like warping, sizing, heat setting, and synthetic fiber spinning.

In some high-speed applications (e.g., Barmag winders, Dienes hot rollers), integrating electrical components, frequency converters, and control panels into the mechanical assembly reduces size and enhances reliability.

Application Examples

Frequency converters are widely used in nearly all textile processes, including:

Spinning: Blowroom, carding, draw frame, comber, roving frame, ring frame, and winding machines.

Weaving: Sizing and warping machines.

Knitting, nonwovens, synthetic fibers, and dyeing machinery.

High-Speed Roving Frame

A modern roving frame developed in China uses industrial PCs, PLCs, and frequency converters to independently control four motors (spindle, roller, bobbin, and lifter), eliminating cone drums and forming mechanisms. Benefits include:

Simplified structure, high efficiency, low noise.

Easy operation and maintenance, reduced yarn breaks.

Maximum speed: 1,500 RPM, with auto-positioning and human-machine interface (HMI).

High-End Sizing Machine

This machine employs distributed AC drives:

Frequency-controlled motors for sizing tanks and drying cylinders.

Servo-controlled motors for warp beams and pull rolls.

5 frequency converters + 2 servo controllers, integrated with pressure, temperature, and moisture sensors.

Controlled via industrial PC + PLC for precise regulation of moisture, temperature, and pressure.

Ensures high precision, stability, and low failure rates, making it a top-tier system.

Conclusion

Frequency converters have become a mature and essential technology in the textile industry. Selecting the right converter helps modernize equipment and improve product quality. As competition intensifies, domestic frequency converter sales are surging. Nanjing Euroverter leads in quality, performance, functionality, and design, offering solutions tailored to diverse customer needs.